10 ton glycol chiller supplier

|

10 ton glycol chiller description |

A 10 ton glycol chiller has a cooling capacity of around 35kw. 10 ton glycol chiller is a safe, efficient, energy-saving, stable refrigeration equipment using glycol mixture as a refrigeration medium, with no ice in the low-temperature environment, will not cause pollution to the environment and other advantages; equipment is widely used in milk, beer, beverages, and other food processing industry.

Taking food fermentation as an example, temperature control is crucial in the process of food fermentation, 10 ton glycol chiller can provide a stable low-temperature refrigeration effect to ensure that the temperature inside the fermentation tank is kept within the ideal range, thus ensuring the normal growth and metabolic activities of microorganisms.

If the temperature inside the food fermenter is too high or too low, it may affect the growth rate of microorganisms and the formation of metabolites, thus affecting the efficiency and quality of fermentation.

In addition, the cold source provided by the glycol chiller can effectively regulate the reaction rate during the fermentation process, making the fermentation process more stable and controllable.

|

Features of the 10 ton glycol chiller |

●Adopting glycol mixture as a refrigerant with a low freezing point;

It can effectively prevent the freezing of the refrigeration circulating pipeline even in low-temperature environments.

●Applicable to the food processing industry: such as wine fermentation, mushroom fermentation, milk, beer, beverage, and other food production industries.

●Adopting secondary subcooling technology, low refrigeration temperature, and fast response speed.

●Adopting ABB, Siemens, Schneider, and other high-quality AC contactors, and intermediate relays.

Longer electrical and mechanical service life, more stable performance.

●Adopt anti-oxidation gas protection welding process: this process ensures that the pipes and connecting parts inside the chiller will not have oxides or impurities remaining after welding, thus ensuring the cleanliness of the system and reducing the negative impact on system performance and service life.

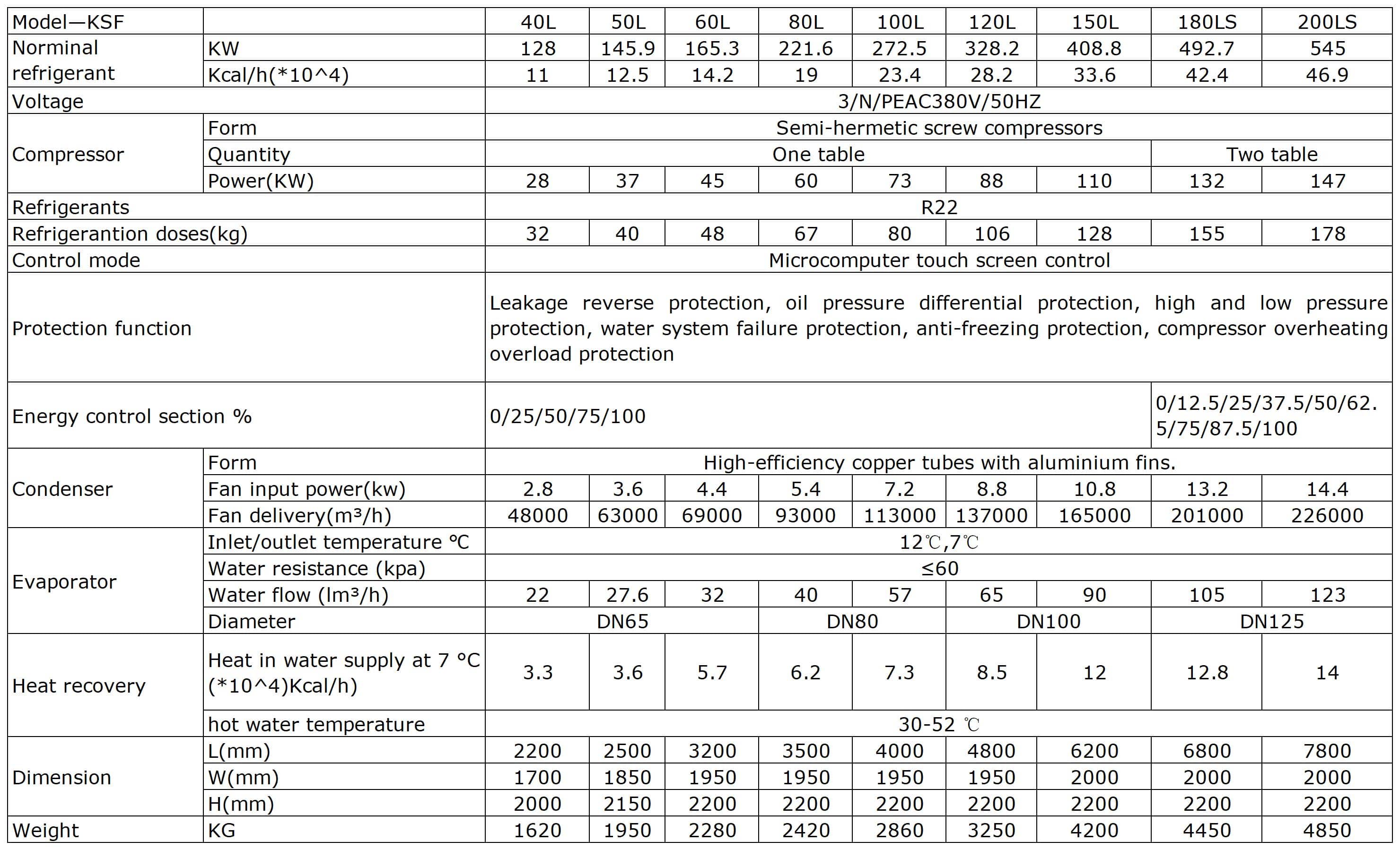

| Technical Specification |

Kassel offers customised products according to customer requirements: cooling capacity, explosion-proof models, high precision, other special requirements, etc.