air cooled screw chiller price

| Product Description |

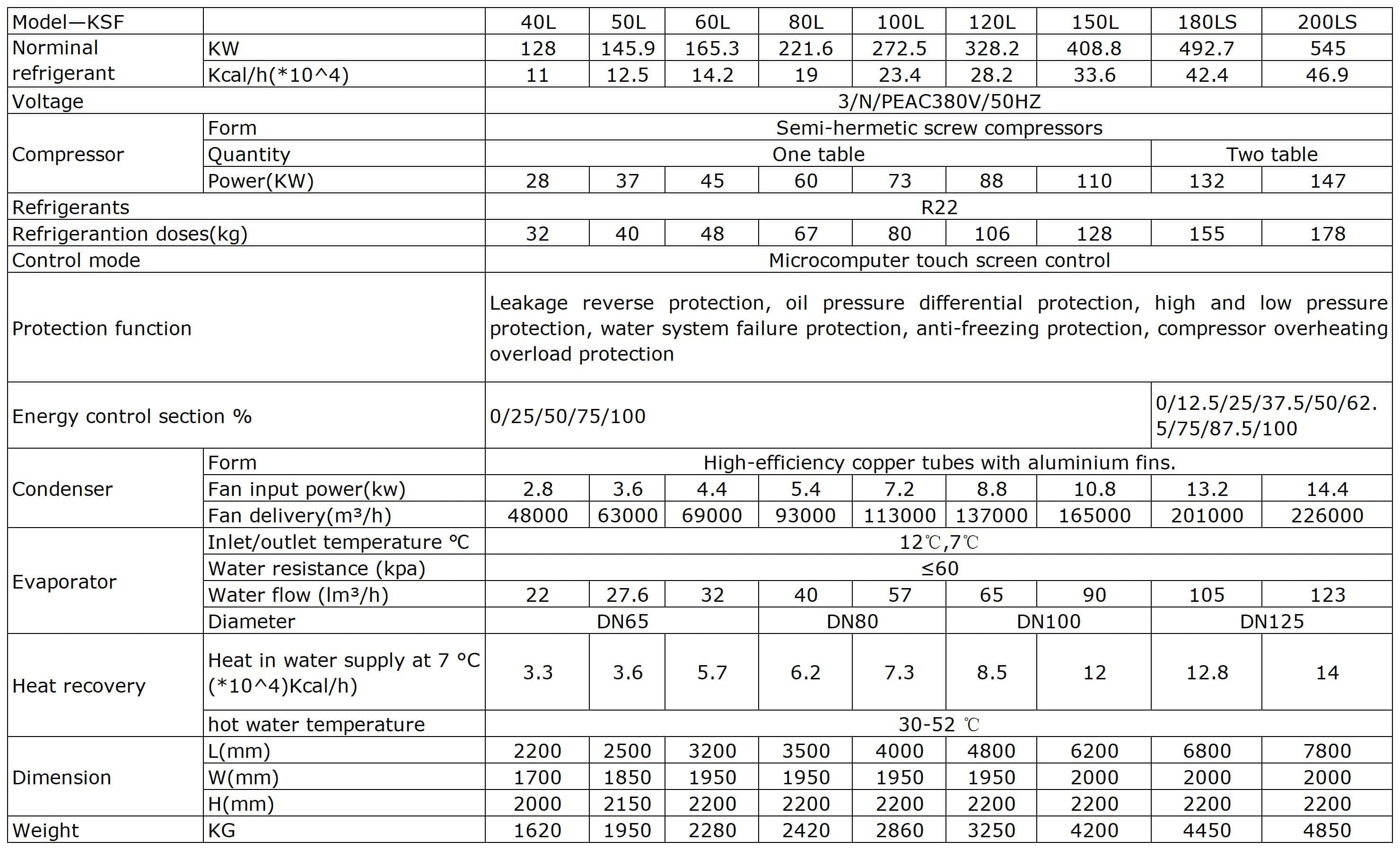

The air cooled screw chiller consists of a compressor, condenser, expansion valve, evaporator, electrical control, etc. It is a kind of cooling equipment that achieves cooling through air heat dissipation. The standard cooling capacity of a KSF air cooled screw chiller varies from 2kW to 545kW. If you have higher cooling capacity requirements, Kassel can customize the product to suit your requirements. The unit uses a fan to cool the refrigerant by dissipating the heat through the air, so there is no need to connect additional cooling water systems such as cooling towers and pumps. Compared with water cooled chillers, it can save certain investment costs in terms of piping installation, cooling water towers, and pumps, making it a cost-effective choice for enterprises. In addition, the installation location of the air-cooled chiller is relatively more flexible, not subject to the restrictions of water supply and water system layout, and is suitable for large-scale central air-conditioning systems, factories, hospitals, office buildings, and other environments and occasions.

|

Features of the industrial water chiller machine |

●Individual refrigeration system design: The air cooled screw chiller contains an independent refrigeration system with core components such as a compressor, condenser, evaporator, and expansion valve. This means that each head can operate independently of the others. This design provides greater flexibility and reliability because if one head fails, the others can still operate normally.

●Multiple refrigeration system design: The unit can start or stop one or more refrigeration systems depending on the environmental demand for cooling capacity and adjust the cooling capacity according to the load demand. Such a design can improve the flexibility and adaptability of the system while reducing energy waste.

●Fewer moving parts and higher stability: the equipment adopts a screw compressor as the core component to realize the refrigeration process, which minimizes the number of moving parts compared to a traditional piston compressor, thus reducing the risk of mechanical failure and effectively improving the reliability and stability of the system.

●Flexible energy regulation design (continuous energy regulation between 25%~100%): air-cooled screw chillers can be flexibly adjusted according to changes in the environment or the system's demand for cooling capacity. When the cooling capacity required by the environment is low, the unit can reduce the cooling capacity to save energy; and when the system demand for cooling capacity increases, the unit can provide more cooling capacity to meet the demand. This ensures that the system can provide appropriate cooling under different load conditions and improves energy efficiency performance, reducing the energy consumption of the enterprise's production operation.

| Technical Specification |

Kassel offers customised products according to customer requirements: cooling capacity, explosion-proof models, high precision, other special requirements, etc.